The to-do list for Aglaya over the winter and in March was long - not least because our boat was on land. This meant that a lot of work could be done that is not possible to do in the water. Aglaya is an old lady. Therefore, we decided to give her a refit with anti-osmosis treatment for the underwater hull.

While we were in Germany during the winter, we had reliable craftsmen here in Kalamata who did the necessary work:

- Sandblasting

- Sanding and repairing damaged areas

- Osmosis protection

- Applying primer and two coats of epoxy

- Two coats of antifouling

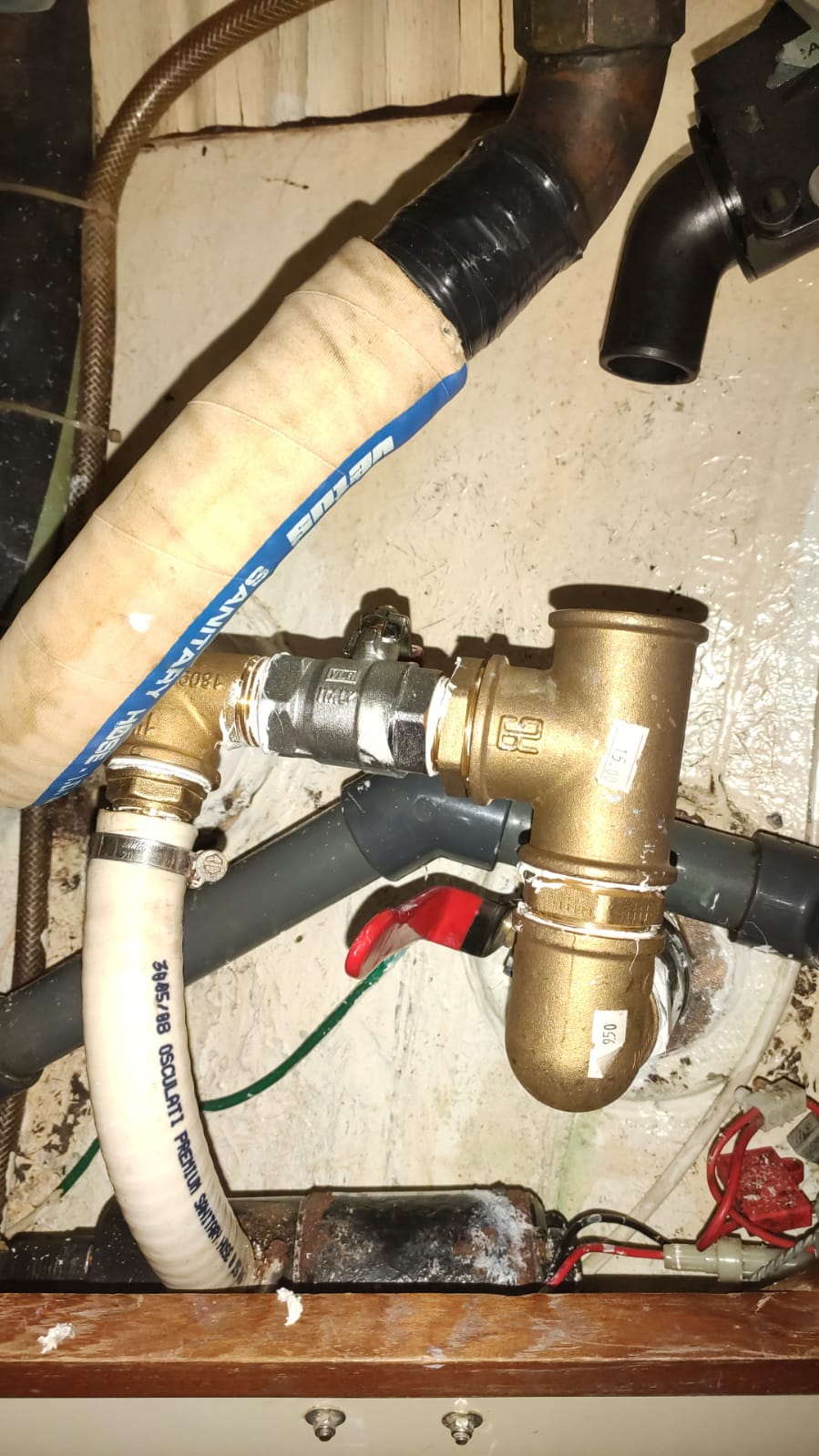

In addition, three seacocks were replaced in the two bathrooms and the drains were cleaned.

This all went well. We kept up with the progress of the work by photos they sent us during our "winter break" at home.

When we were back at the boat on the 11th of March, the work continued - and more than we had expected. The propeller was removed, grinded and polished. During re-installation, a ring for cutting lines was also included. Hopefully it won't be needed! The anodes on the rudder and shaft were renewed, also those at the water collector of the exhaust.

Of course there was also the usual maintenance work. We cleaned the GFK on the hull and deck, treated it with a light abrasive and wax and then polished it. And of course, all the metal on deck had to be cleaned of dirt and rust and polished again. This maintenance work is not only to improve the appearance (Aglaya should of course shine at the beginning of the new season), but above all for protection from salty air and salt water. The teak deck will be maintained when the boat is in the water.

Grinding and Polishing: Video

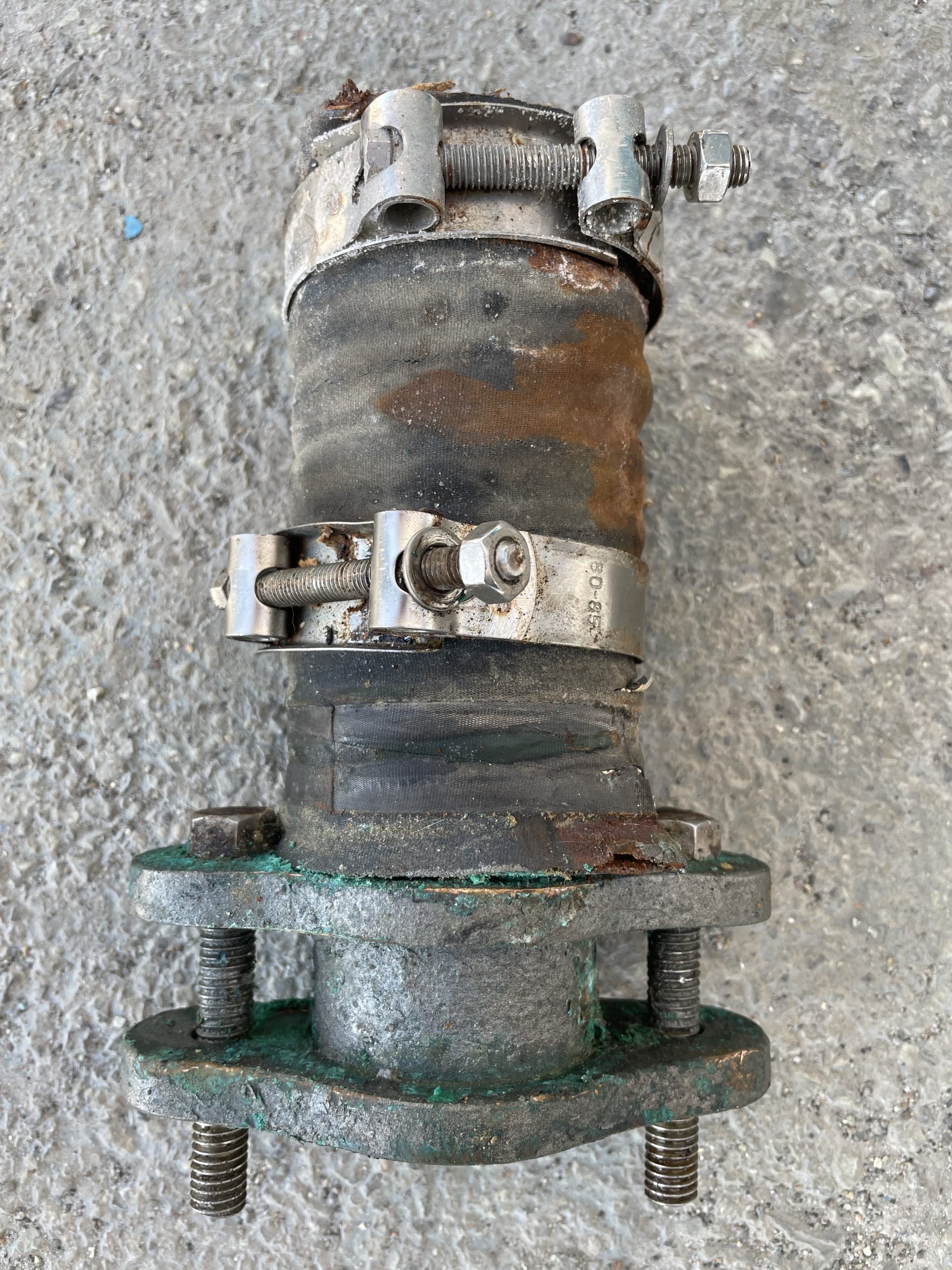

And then there was the matter of the clearly too much water in the bilge in the engine room. Where did that come from? At the end of the season last year we couldn't find out. So now the stuffing box has been removed, a nice gland with a lot of corrosion. Our trusted mechanic cleaned it and replaced the packing inside. When we reassembled it, it turned out that the motor was two centimetres too low, pushing the shaft up. So that's why it was running so hard. We had already noticed that. But how did that come about? We don't know. The mechanic had an exhausting job: Without further ado, he put the engine two centimetres higher. Another thing we couldn't have done ourselves. Now the propeller turns easily.

Compared to such hard work, the replacement of the water tap in the pantry and a new durable coat of paint on the wooden surfaces at the stern were easy.

And for safety, a new liferaft and a lifesling are coming on board. This required minor modifications to the railing.

Hopefully we will soon be back in the water (we are still parked at the moment). Once the stays, which have to be partially removed for the travel lift, are properly tightened again, we can finally hoist the sails.